Use this option to draw from offcuts (scrap) to make the finished item for a customer order.

Refer to "Selecting the Customer Job Card to be Completed".

Refer to "Allocating from Coil Stock - All" or "Allocating from Coil Stock - Prime".

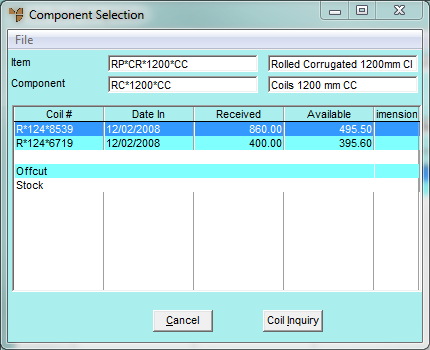

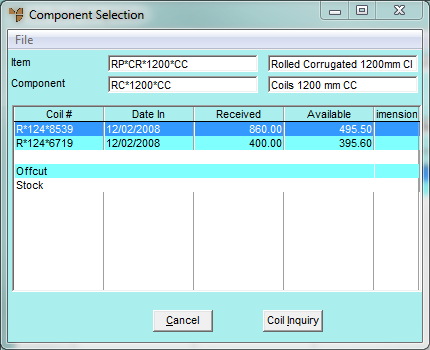

Micronet displays the Component Selection screen.

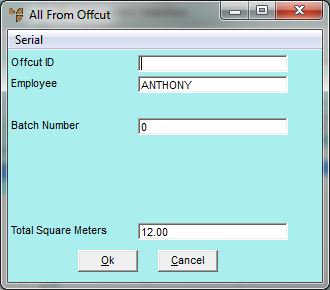

Micronet displays either the All From Offcut screen or the Prime From Offcut screen, depending on the option you selected.

|

|

Field |

Value |

|

|

Offcut ID |

On the All From Offcut screen, enter the offcut part number you want to draw from (usually a diminishing part number SCRAPxxxxxx). You can also press Tab or Enter to select an item. |

|

|

Manufactured Product |

On the Prime From Offcut screen, Micronet displays the item number of the item to be manufactured. |

|

|

Component |

On the Prime From Offcut screen, enter the offcut part number you want to draw from (usually a diminishing part number SCRAPxxxxxx). You can also press Tab or Enter to select an item. |

|

|

Employee |

Enter your employee ID, or press Tab or Enter to select from a list. Employee IDs are setup in the Employee master file in either the Distribution or Job Costing systems (refer to "File - Employee"). |

|

|

Batch Number |

This is an optional field which can be used for quality assurance tracking. The batch number is usually the number from your roll forming computer batch control system. |

|

|

Quantity |

On the Prime From Offcut screen, Micronet displays the quantity of the component item on the original order. You can change this if required. |

|

|

Length |

On the Prime From Offcut screen, Micronet displays the length of the item per unit. You can change this if required. |

|

|

Total Square Metres |

Enter the total square metres of offcut you are going to take for this job. |

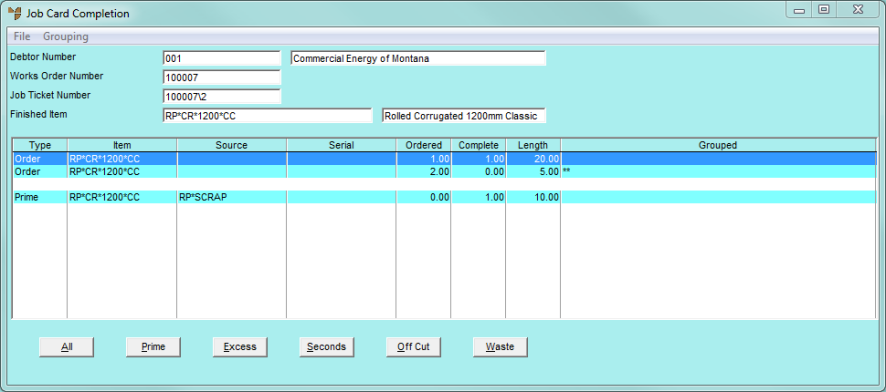

Micronet displays the Job Card Completion screen showing the Source as being from Offcuts, along with the quantity completed.

Refer to "Allocating By-Products of a Job".

Refer to "Maintaining Job and Store Cards".

Refer to "Completing Job and Store Cards".